Connection of the pipes

In the construction phase: stripping and sleeving of the pipes

In the construction phase, the connection between the pipes is achieved through simultaneous stripping and sleeving.

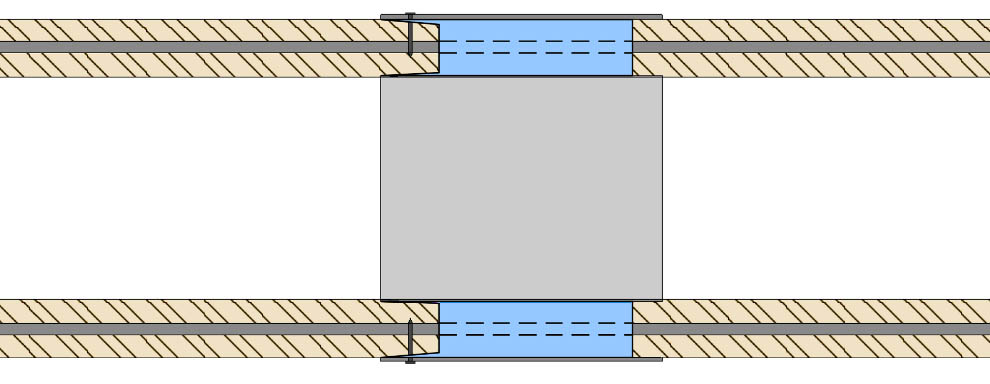

Stripping during the presentation of the two contiguous pipes, because the extending tubes of one of the pipes enter into the other pipe until mutual abutment of the tubes of one pipe on the precast UHPFRC of the other.

Sleeving because the exterior and interior collars partially cover the end of the two contiguous pipes and create an external sleeve and an internal nipple. To perfectly maintain the sleeve in its set position, the outside collar is bolted.

In definitive phase: continuous connection and sealing

The ring corresponding to the volume delineated by the sleeve and the nipple is filled with UHPFRC.

The volume of the ring is 7.8 litres.

The UHPFRC is kneaded, mixed and transported to the sleeve by a small mixer-pump unit of the Bunker or Putzmeister type.

The extending tubes of the segments are coated with fresh UHPFRC between the collars.

In the long term, the hardened UHPFRC of the ring will provide the continuity of the consecutive segments through coating the tubes and adhesion to UHPFRC (in light blue on picture below).

The nipple provides the sealing of the joint.

A continuous and water-proof connection of the type of a welding connection between two metal pipes is thus obtained.